Researchers from BGU and the University of Western Australia are the first and only research group in the world to be able to produce sizable amounts of special valued closed-cage, hollow "nano-onion" structures from boron nitride (BN). NASA, the US space agency, has already requested samples of BN nano-onions for tests geared toward use on US satellites.

At less than one-thousandth the diameter of a human hair, their size, hollow structure and crystalline nature, coupled with their chemical properties, make them remarkable lubricants for use in high-temperature and high-pressure applications where conventional lubricants are inadequate, most notably aerospace systems. BN nano-onions can also be introduced into 3D printers to increase the tensile strength of the matrix material without increasing weight.

Professors Jeffrey Gordon (BGU) (left) and Hui Tong Chua (UWA) alongside the lamp ablation facility they designed and built at UWA, in which the exciting advance of BN nano-onions was generated.

Professors Jeffrey Gordon (BGU) (left) and Hui Tong Chua (UWA) alongside the lamp ablation facility they designed and built at UWA, in which the exciting advance of BN nano-onions was generated.However, the hollow closed-cage BN nano-particles have proved especially elusive until now. Prof. Emeritus Jeffrey Gordon of BGU’s Department of Solar Energy & Environmental Physics in the Jacob Blaustein Institutes for Desert Research and Prof. Hui Tong Chua of the Chemical Engineering Department at the University of Western Australia (UWA) have succeeded in synthesizing BN nano-onions in sizable amounts, in a one-step process that is safe (devoid of any toxic substances), rapid and, most importantly for the possibility of having large-scale impact, amenable to scale-up.

A provisional patent application has been filed for the technology, and an agreement with Innovyz Advanced Materials and Manufacturing Pty Ltd (Innovyz) of Adelaide, Australia has been executed which provides Ablano (a start-up owned by Innovyz) with an 18-month option to license the technology technology invented by Prof. Chua and Prof. Gordon, who are now collaborating with industry experts sourced by Innovyz to scale up the technology and fast track its commercialization.

Their achievement was also published last year in a leading journal in the field,

Nano Research.

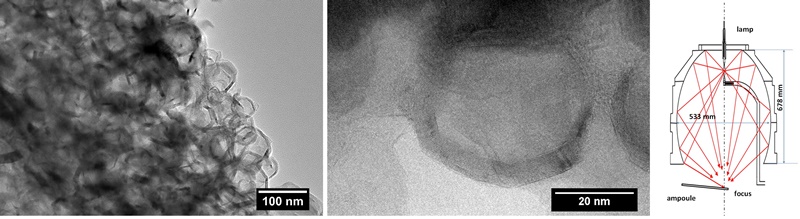

(Left) Transmission electron microscope image of clusters of BN nano-onions, which intimate the significant yields that can be achieved with the new method developed in the BGU-UWA collaboration. (Center) A magnified view of an individual nano-onion. (Right) A schematic of the lamp ablation optical system.