Technical description of the Lab

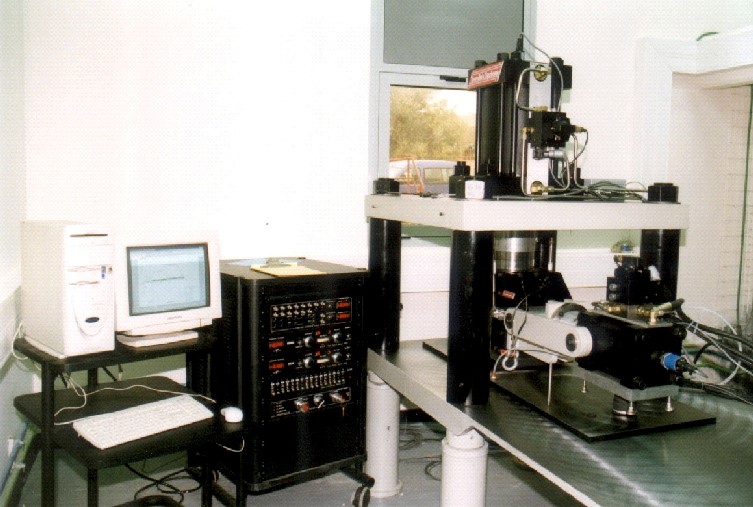

1. THE TRIAXIAL SYSTEM: Hydraulic, stiff, closed-loop servo controlled triaxial system. Load frame stiffness 5*109 N/m (TerraTek model FX-S-33090). Two control modes are possible for the axial piston: Load and Displacement. Axial force capacity: 1.4 MN. Confining pressure capacity: 70 MPa. Simultaneous electronic measurement of axial and radial strain using a two special four arm strain cantilever system sets with a maximum strain range of 7%. Precision: 0.25 - 0.5% linearity full scale on all strain/displacement transducers as well as load cells. Two load cells (LC) are currently in service: 1000 kN LC for strong rocks, and a 222 kN LC for weak rocks to allow for better resolution in low stress measurements. Using the close-loop system the following tests can be performed:

· Unconfined Compression tests

· Triaxial Compression tests

· Post Peak tests

· Creep tests

· Hydrostatic Compression tests

· Segment tests

· Uniaxial Strain tests

The 1.4 MN Load Frame at the Rock Mechanics Laboratory of the Negev, with the 70 MPa confining pressure vessel. Top and Left: The four arm radial and axial strain cantilever system. Right- The load frame and pressure vessel.

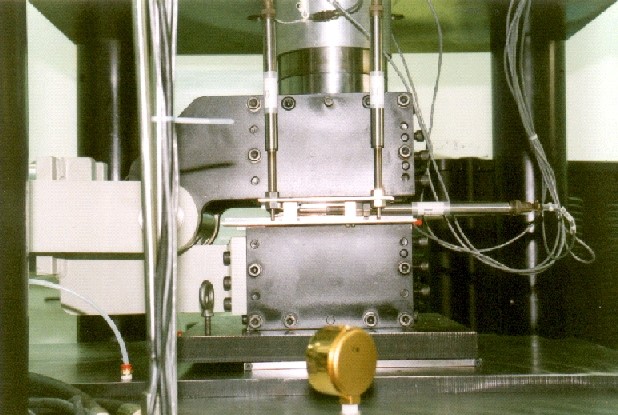

2. THE DIRECT SHEAR SYSTEM: Hydraulic, stiff, closed-loop servo controlled, direct shear system. Load frame stiffness 7.0 MN/m (TerraTek DS - 4250).Normal force capacity: 1000 kN, Shear force capacity: 300kN. Shear box dimensions: 150mmX150mmX300mm. Normal load measured with a 1000kN LC with 0.5% linearity full scale. Shear load measured with a 300 kN LC with 0.5% linearity full scale. Vertical (normal) displacement measured with four 50mm range LVDT's with 0.25% linearity full scale. Shear displacement measured with two 50mm range LVDT's with 0.25% linearity full scale.

The direct shear system load frame

The shear box with four normal displacement and two shear displacement LVDT's .

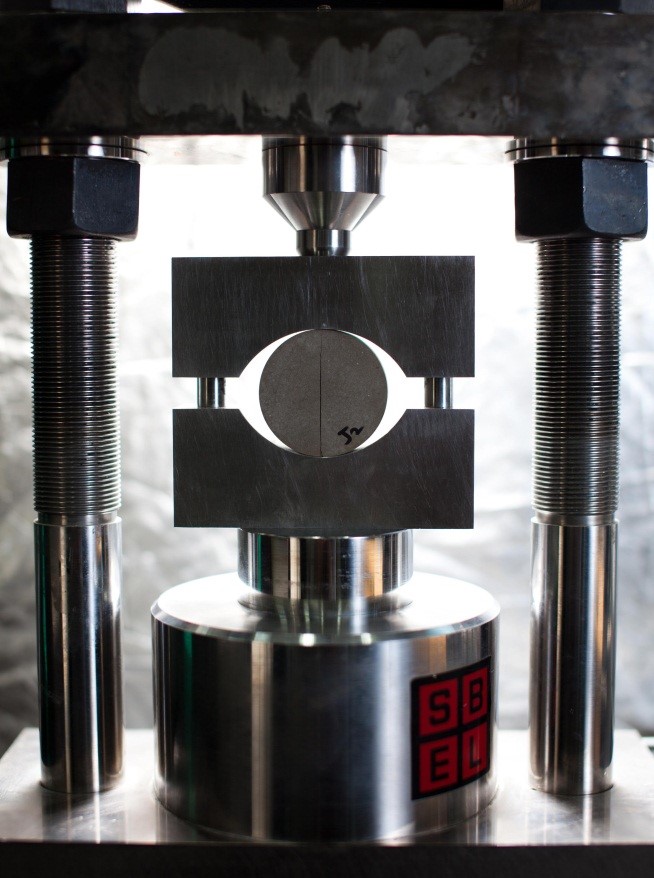

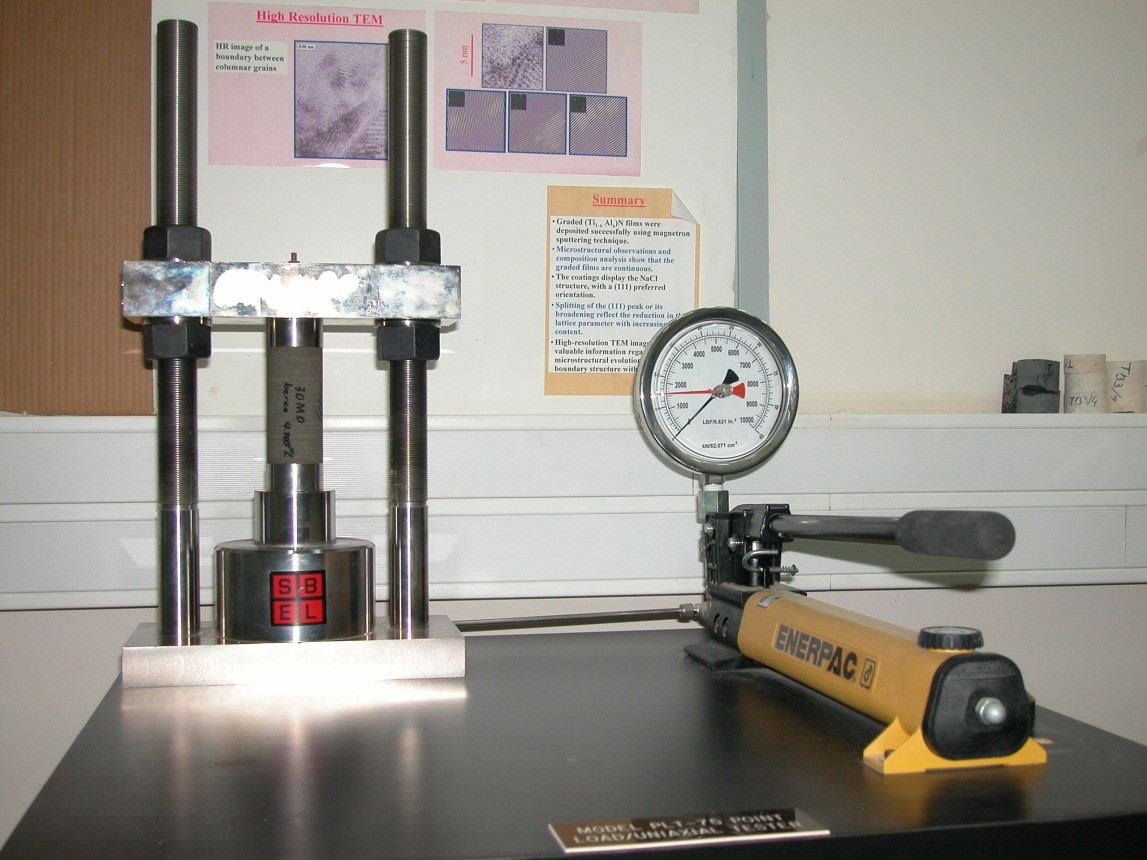

3. BRAZILIAN , POINT LOAD, AND UNCONFINED COMPRESSION MINI LOAD FRAME: Manual, hydraulic, mini-load frame for Brazilian, Point Load, and Uniaxial tests according to ASTM and ISRM standards (SBEL model PLT-75). Enerpac P391 hydraulic manual hand pump with pressure capacity of 70 MPa.

The manual mini–load frame for tensile strength Brazilian tests (SBEL model PLT-75)

The manual mini–load frame for tensile strength Brazilian tests (SBEL model PLT-75)

The manual mini–load frame for compressive strength Point load tests (SBEL model PLT-75)

The manual mini–load frame for compressive strength Point load tests (SBEL model PLT-75)

The manual mini–load frame for Uniaxial tests (SBEL model PLT-75)

The manual mini–load frame for Uniaxial tests (SBEL model PLT-75)

4. ULTRASONIC WAVE VELOCITY

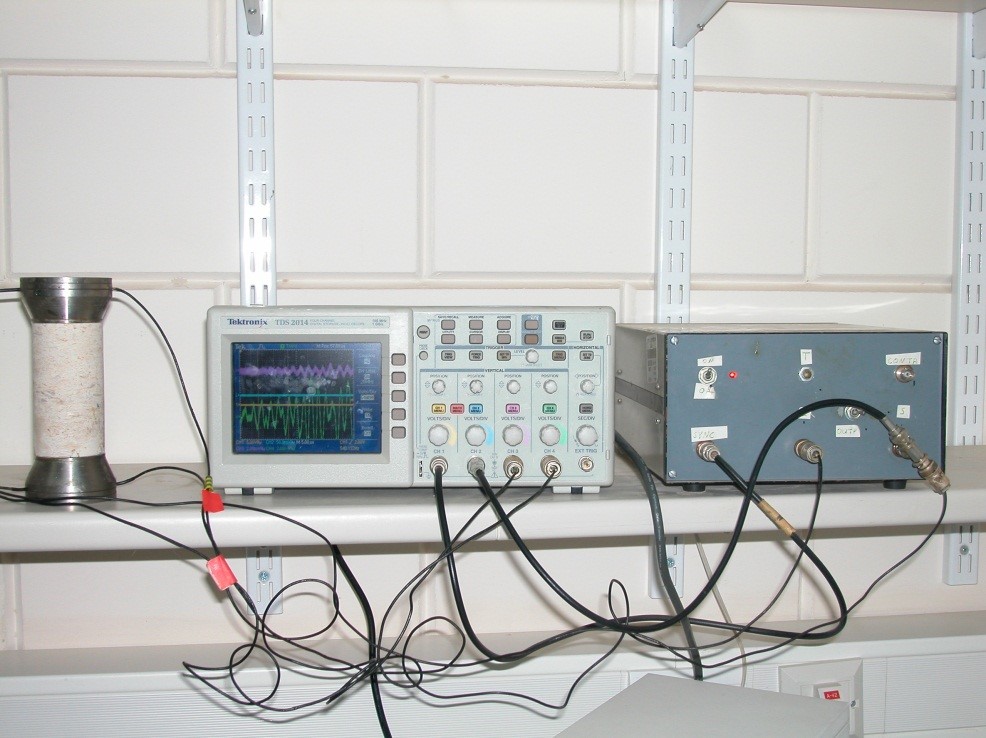

· Table top ultrasonic wave velocity system. Electronic unit produces rectangular radio wave pulses and rectangular synchronous impulses following with the repetition frequency of radio wave pulses. Carrier frequency of radio wave pulses adjusted within the limits of 300-1200 kHz. Radio wave pulse amplitude at minimum 10 V with loading of 50 Om. Oscilloscope Tektronix TDS 2014. Suitable for 54 mm diameter cores with length/diameter ratio of 2.

Table top ultrasonic velocity measurement device for determination of Longitudinal (P) and Transverse (S) waves in solid cylinders of rocks.

Table top ultrasonic velocity measurement device for determination of Longitudinal (P) and Transverse (S) waves in solid cylinders of rocks.

· Pressurized acoustic velocity system AVS350 manufactured by Vinci Technologies suitable for 1'' diameter plugs of 1''-3'' length. Axial, radial and pore pressure are independently controlled with Enerpac P391 hydraulic manual hand pump (pressure capacity of 70 MPa) and manifold pressure capacity of 35 MPa. Tests can be performed on dry, moist or saturated samples whereas the saturating fluid is of choice. Electric signals are being generated and received by Olympus Impulser 5072PR. Ultrasonic transducers of 500 kHz frequency. Waveforms are seen over Oscilloscope Tektronix TDS 2022C and data is exported to the station computer. Heating mantle with temperature range of ambient to 150°C. Pressures are controlled with Swagelock type valve. Stainless steel manifold with 1/8'' tubes. Pore pressure floating piston made of stainless steel and pressure capacity of 70 MPa.

AVS350 device for determination of Longitudinal (P) and Transverse (S) waves in solid cylinders of rocks with pressurized saturated plugs.

5. POROSITY AND PERMEABILITY

· PHI 220 semi- auto Helium Porosimeter manufactured by Coretest System, Inc. This device is intended for direct grain volume measurements. Plug diameter of 1'' or 1.5 '' and length of 1'' to 3''. Void space accuracy range of 0.05-25 cc. Helium pressure inlet of 250 psi with 1/8’’ Swagelock valve.

PHI- 220 device for porosity and grain density determination.

PHI- 220 device for porosity and grain density determination.

· Coreval 30 automatic Permeameter and Porosimeter manufactured by Vinci Technologies. Porosimeter function is intended for direct pore volume measurements at 400 psi confining pressure and maximum 250 psi pore pressure using nitrogen source. Plug diameter of 1'' or 1.5 '' and length of 1'' to 3''. Permeability test methodology of unsteady state conditions, better used in impermeable samples. Permeability range of 0.1 to 5,000 mD. Porosity range of 0.01-60%. Power source 110/240 VAC, 50 or 60 Hz. Air pressure of 125 psi.

· Coreval30 device for determination of porosity, grain density, gas permeability, corrected liquid permeability, gas slippage factor “b”.

· Coreval30 device for determination of porosity, grain density, gas permeability, corrected liquid permeability, gas slippage factor “b”.

6. SAMPLE PREPARATION LAB: Sample preparation lab, fully equipped with a high precision drill press (Cincinnati Milacron PC 32), one blade saw, high precision dual blade saw with 1'' separation (ASC scientific S1-220), and surface grinder (Equiptop ESG 2A618). NX size solid cylinders are prepared according to ASTM and ISRM standards regarding end roughness (smaller than 0.02mm) and perpendicularity (to within 0.005 radians).

· Soils Classification Equipment (ASTM).

· Rock classification Schmidt Hammer test device by CONTROLS S.r.l item 588-C0185 (ASTM, ISRM).

· Slake durability test device by CONTROLS S.r.l item 45-D0546 (ASTM, ISRM). 2mm standard mesh. Drive shaft rotating at 20 rpm. Suitable for 450-550 grams of rock divided equally to 10 samples.

· Thermal conductivity measurements using non-steady-state-probe (NSSP) according to ASTM D 5334-00 and D 5930-97 standards. A 2.5 mm diameter hole is drilled at the center of cylindrical rock sample with a diameter of 68 mm a height of 48 mm. A 1.2 mm diameter thermo-resistance needle is used as both heating wire and as a temperature sensor at the source.